Share to

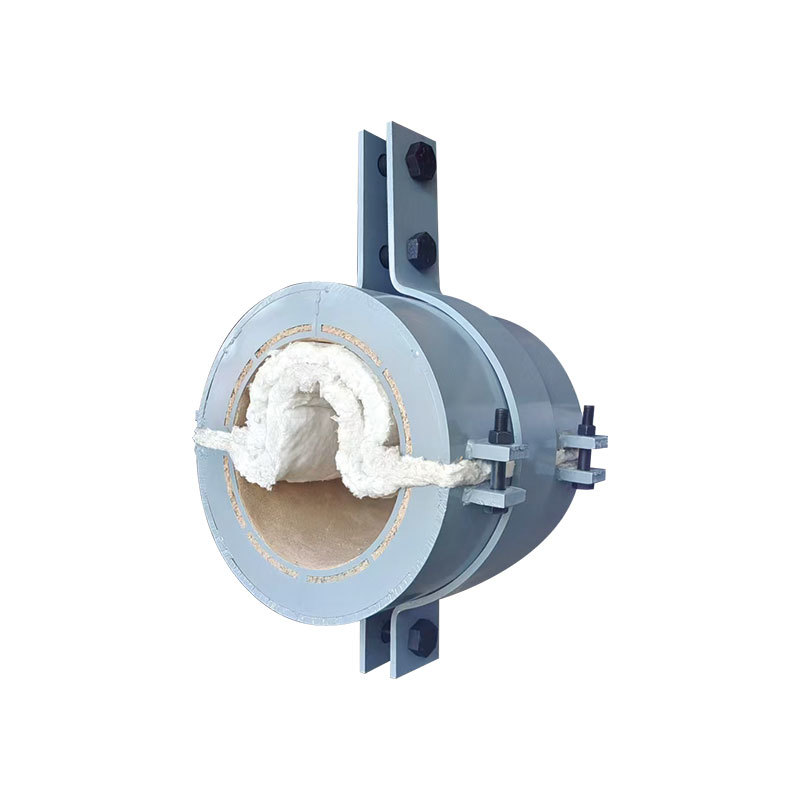

Special dynamic pipe clamp type with angle spring shock absorber

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

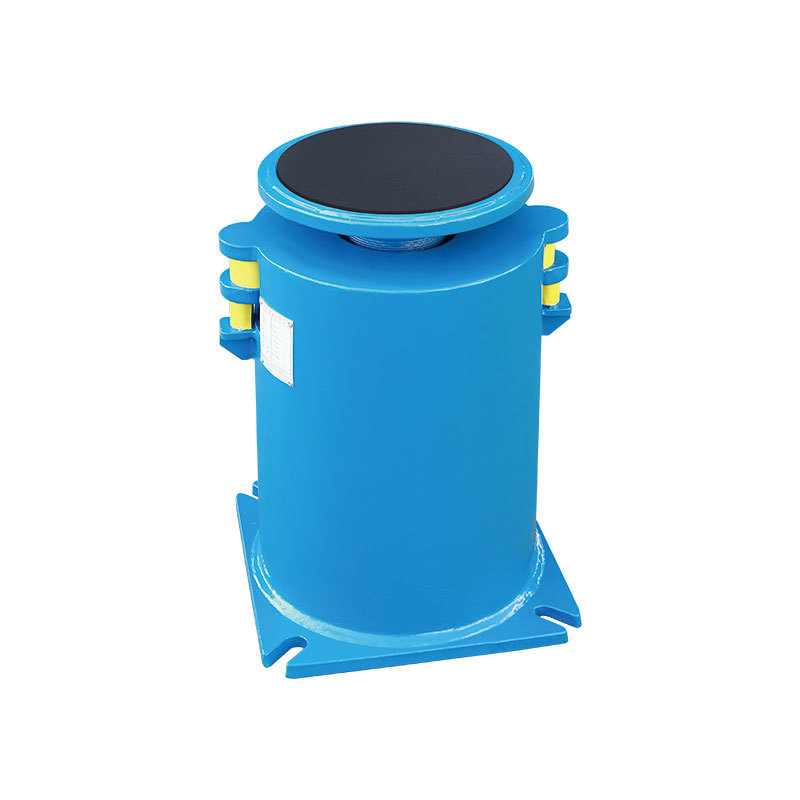

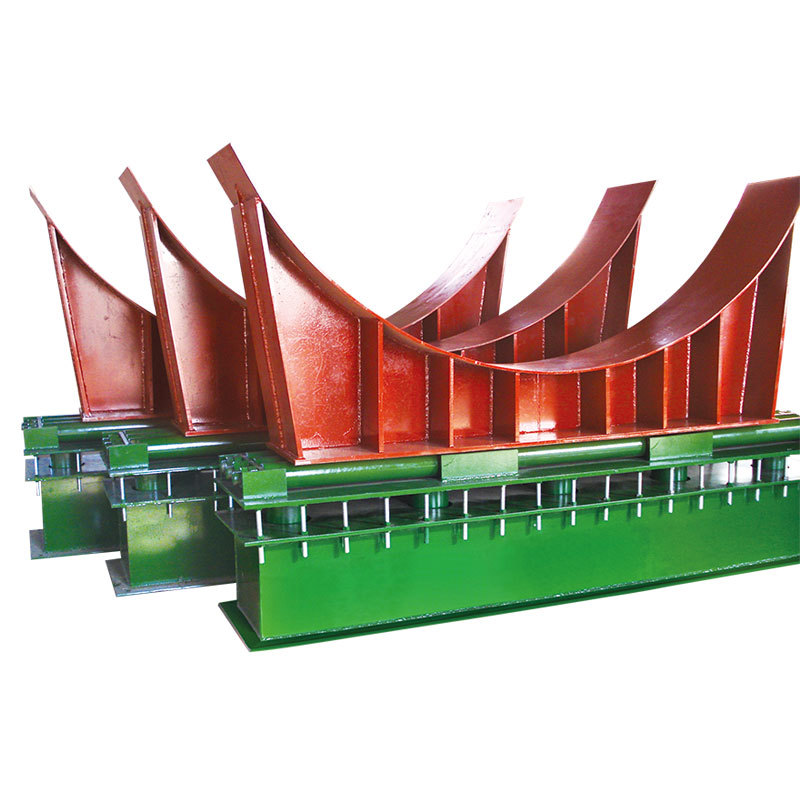

The spring shock absorber belongs to the hanger category and is a vibration control device that is sensitive to displacement. It is commonly used to control the vibration of the pipe system due to continuous fluid vibration disturbances (such as fluid pulsation, two-phase flow, high-speed flow and wind vibration, etc.).The use of spring shock absorbers can effectively reduce and eliminate the vibration during the operation of the pipeline, and the vibration and shock of the steel beam through the pipeline suspension frame.

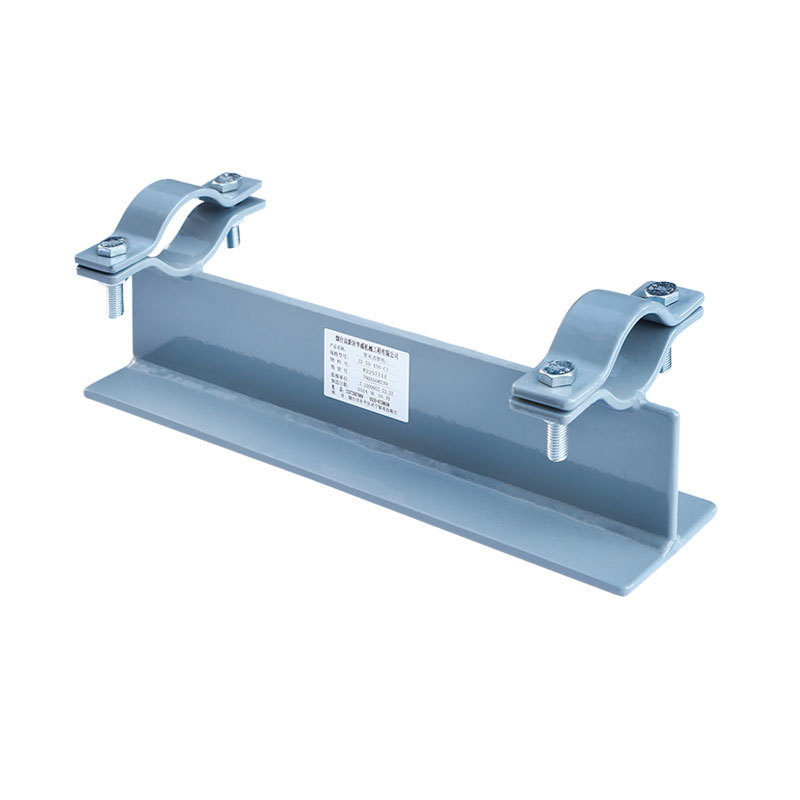

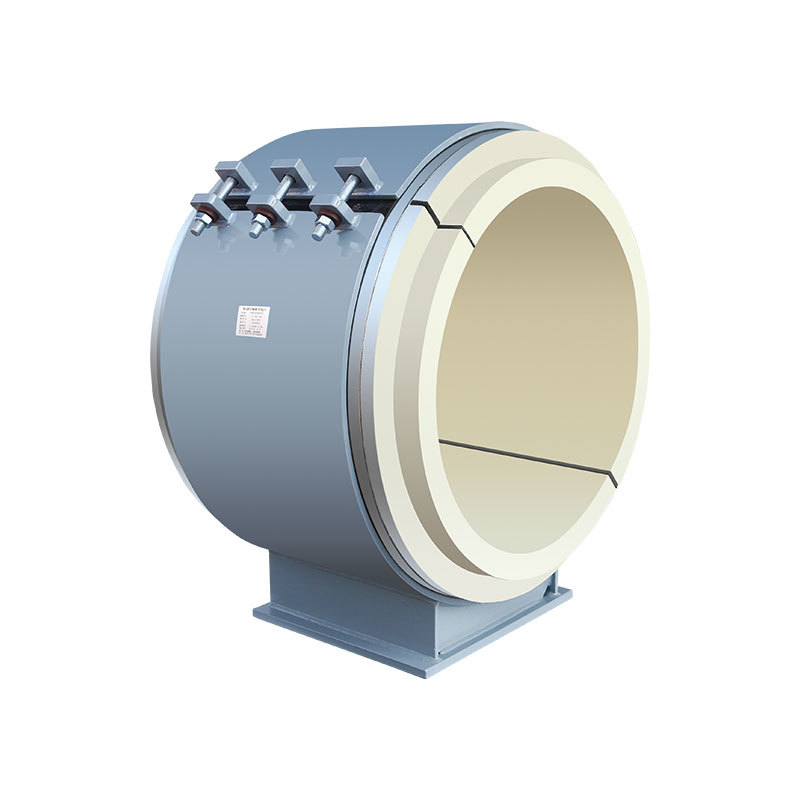

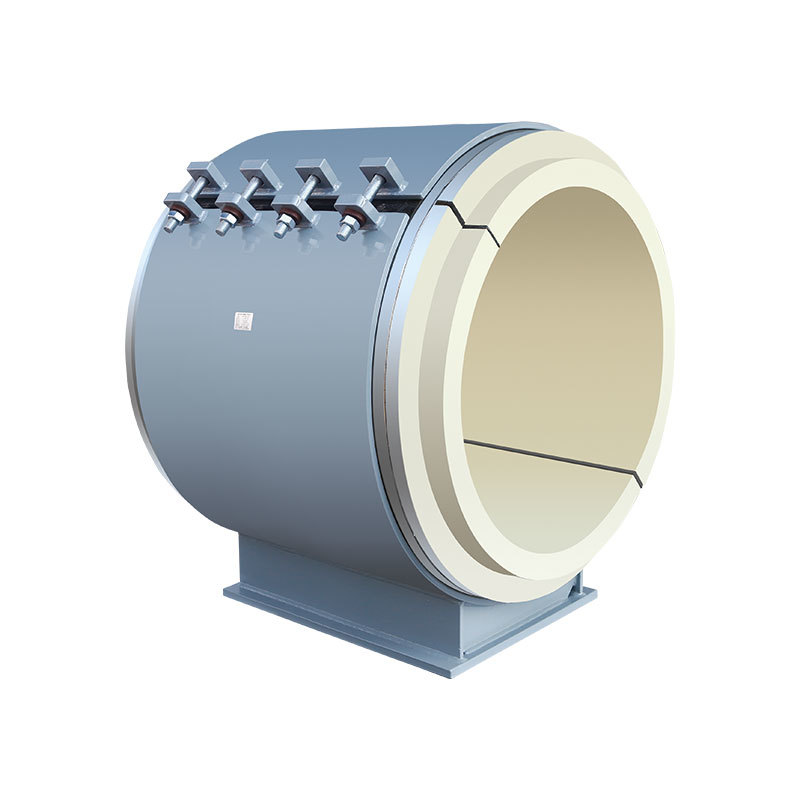

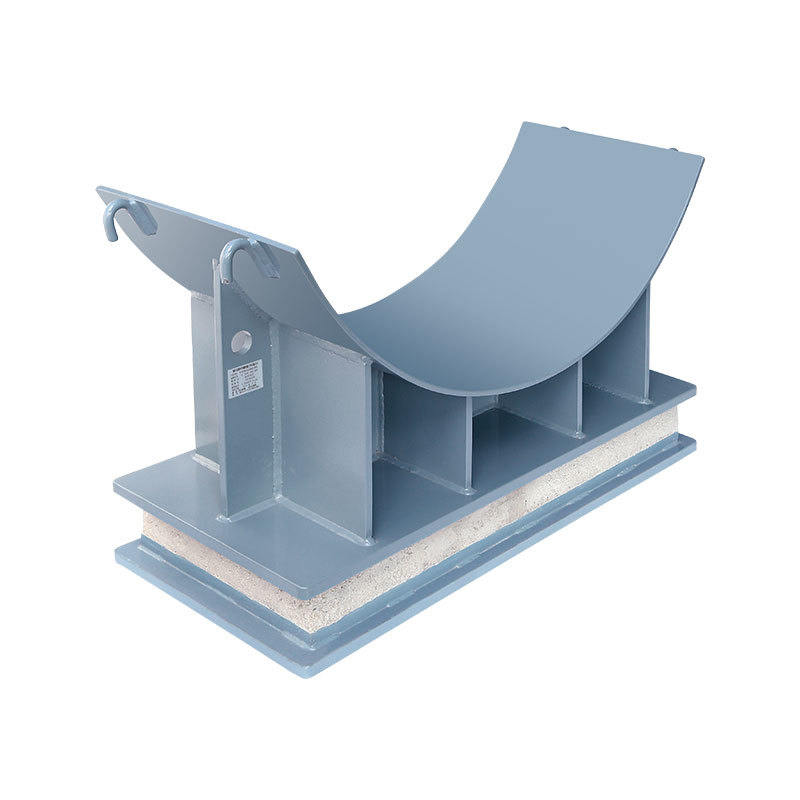

According to the connection method between the spring shock absorber and the pipe or pipe trunnion, it can be divided into pipe clamp type spring shock absorber and welded type spring shock absorber.

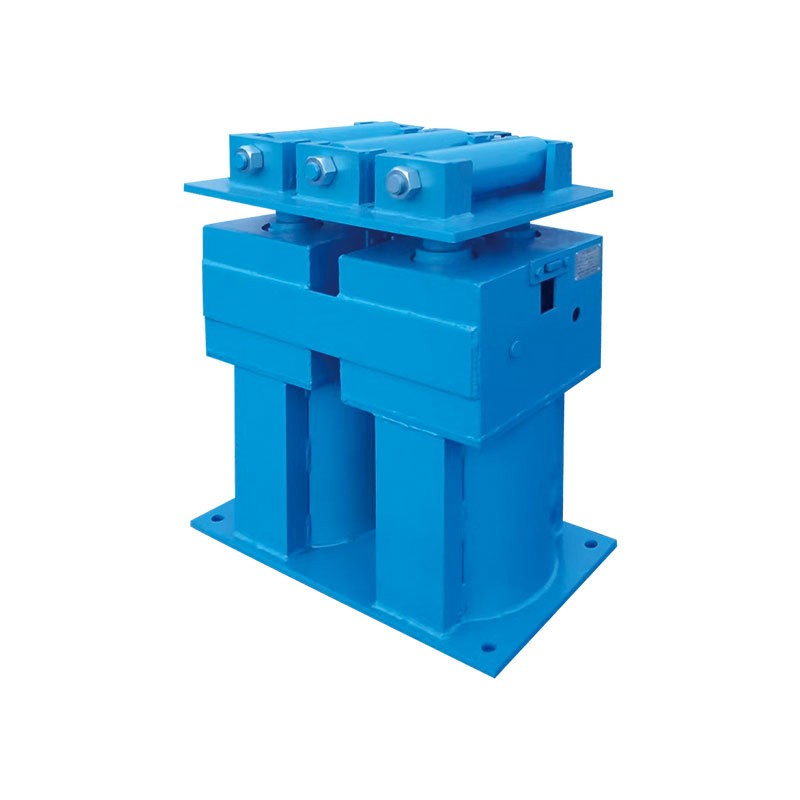

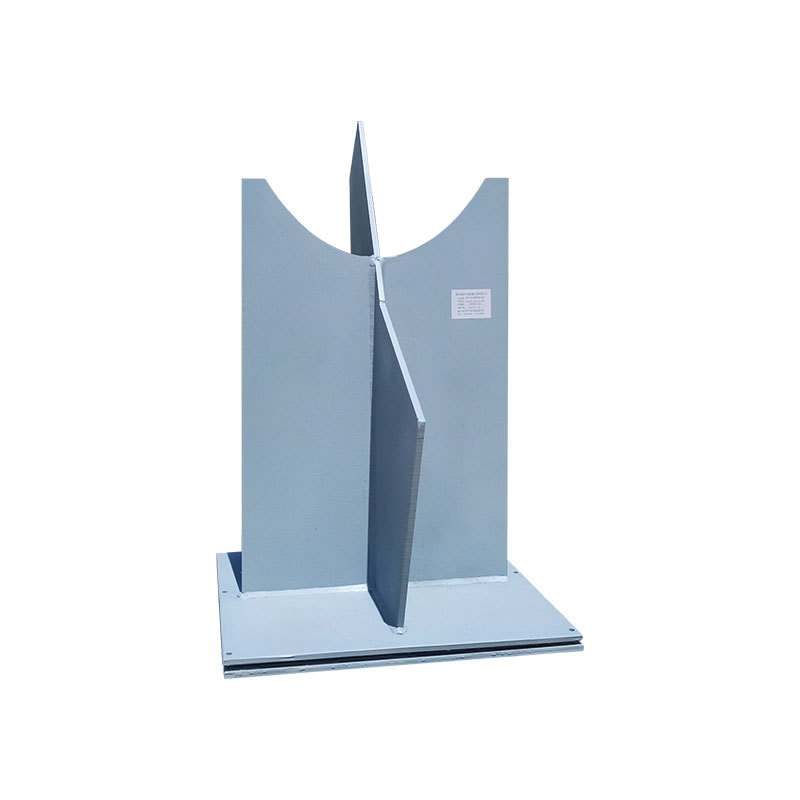

The spring shock absorber is composed of an upper pin seat, a joint bearing, an adjustment nut, a spring assembly, an adjustable connecting tube, a support rod, a lower pin seat or a dynamic pipe clamp.Refer to the HG/T21629-2021 standard atlas for its typical installation form.

Typical installation form of spring shock absorber

Name

Name code

Description

Product example

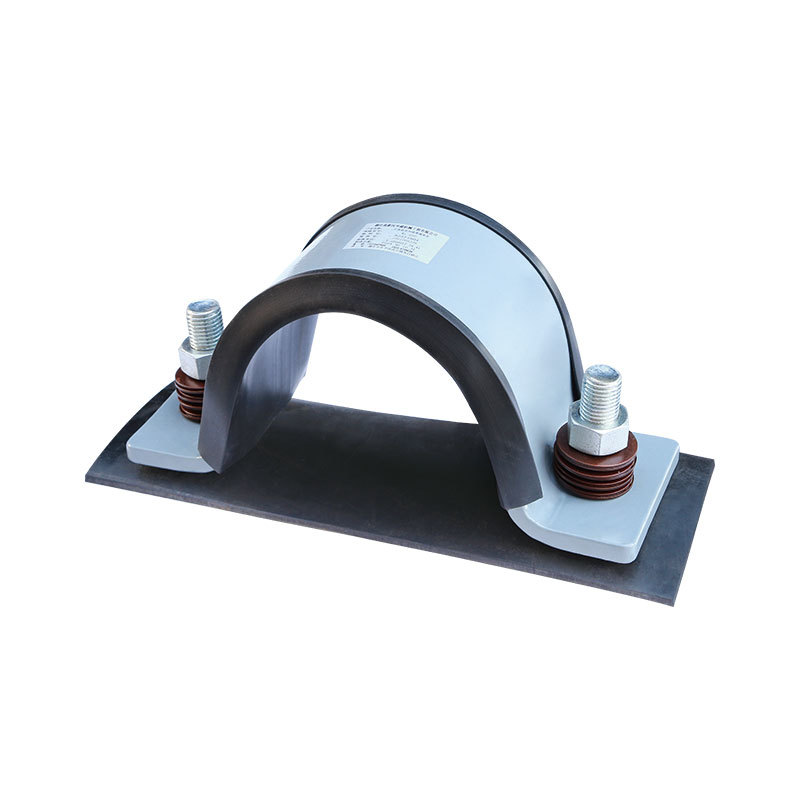

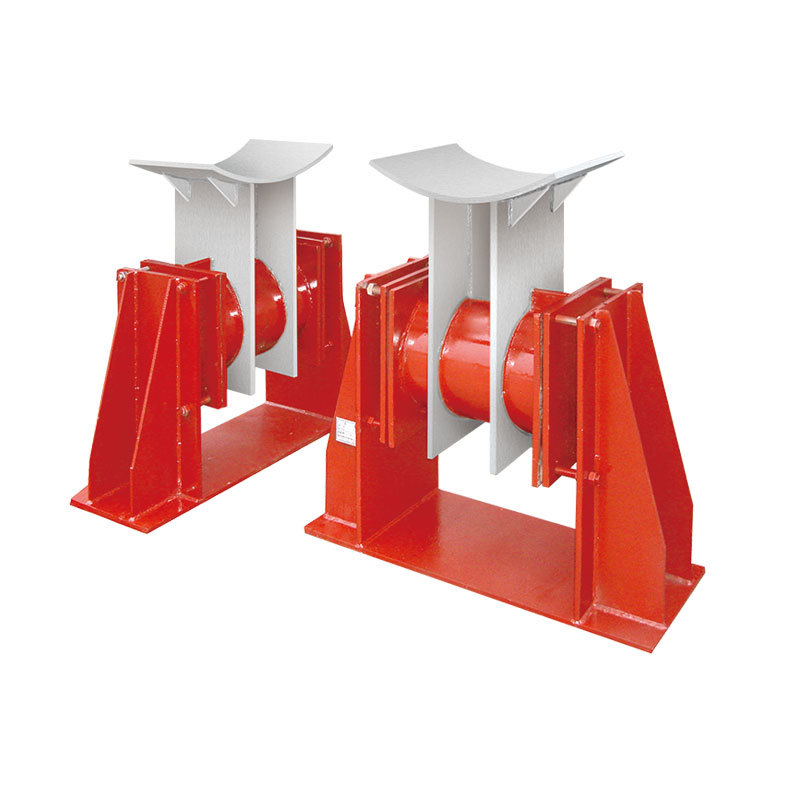

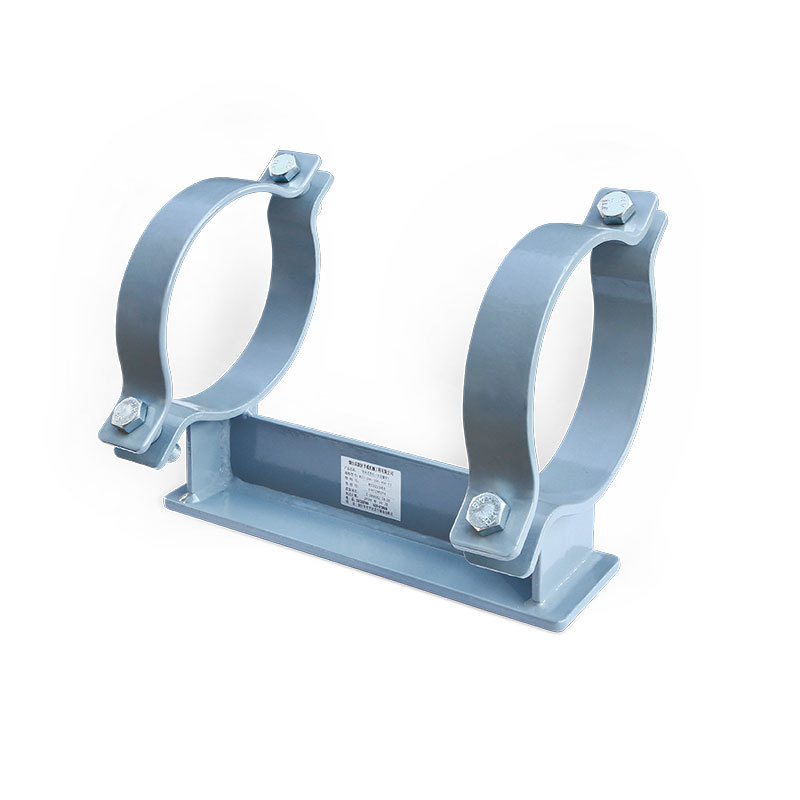

Pipe clamp type spring shock absorber

X1

The upper pin seat is welded to the upper steel beam, and the dynamic pipe clamp clamps the pipe or pipe trunnion

31

Pipe clamp type spring shock absorber (straight tube trunnion)

X2

The upper pin seat is welded to the upper steel beam, and the dynamic pipe clamp clamps the straight pipe trunnion (horizontal pipe, vertical pipe)

Same as 31

Pipe clamp type spring shock absorber (elbow trunnion)

X3

The upper pin seat is welded to the upper steel beam, and the dynamic pipe clamp clamps the straight pipe trunnion (elbow)

Same as 31

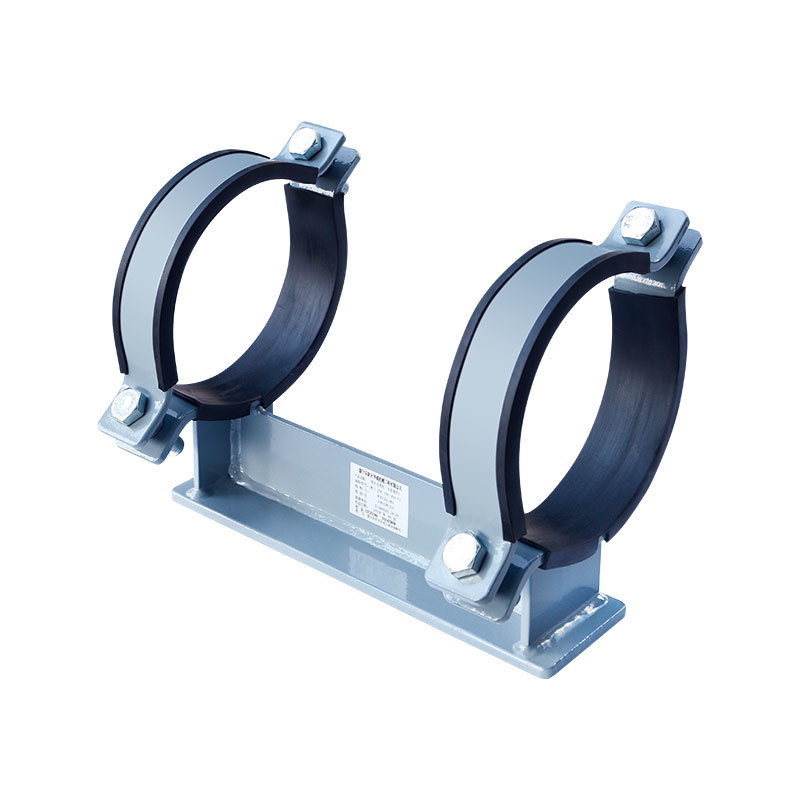

Pipe clamp type spring shock absorber (double trunnion)

X4

The upper pin seat is welded to the upper steel beam, and the dynamic clamp clamps the trunnions of straight pipes (horizontal pipes, risers) on both sides of the pipe.

Same as 31

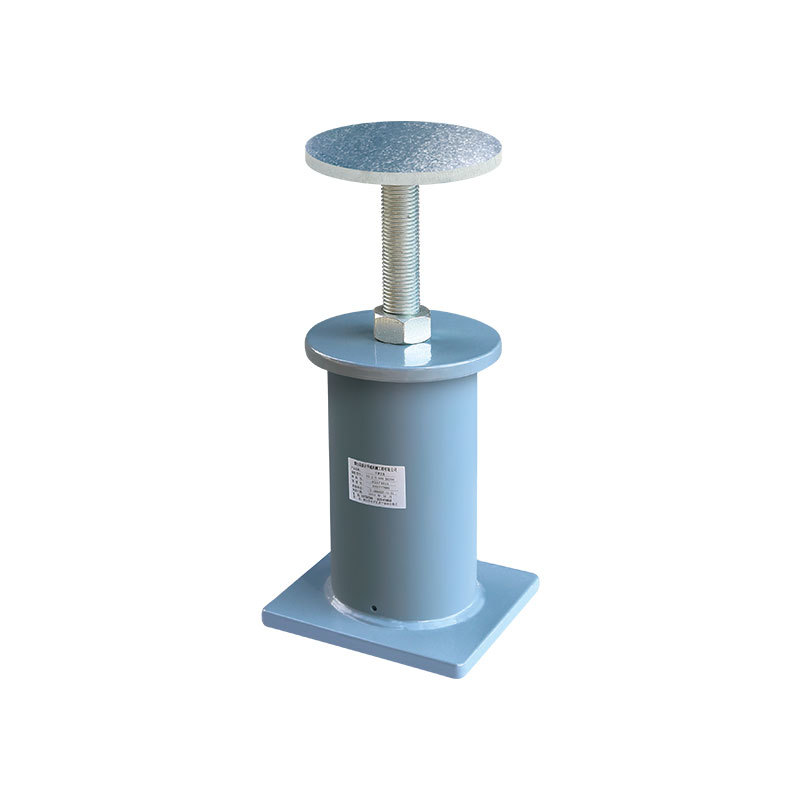

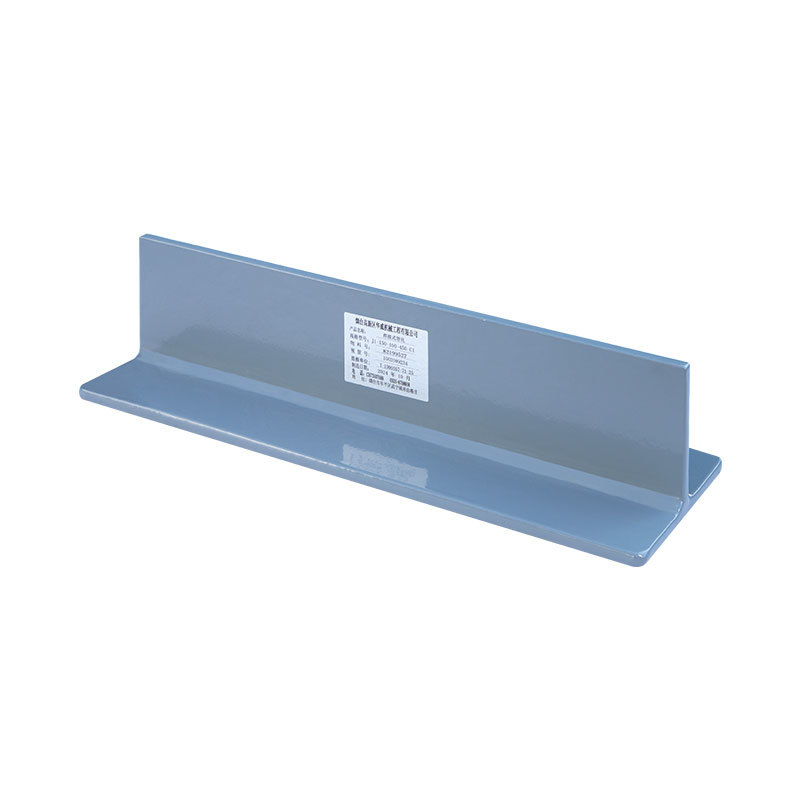

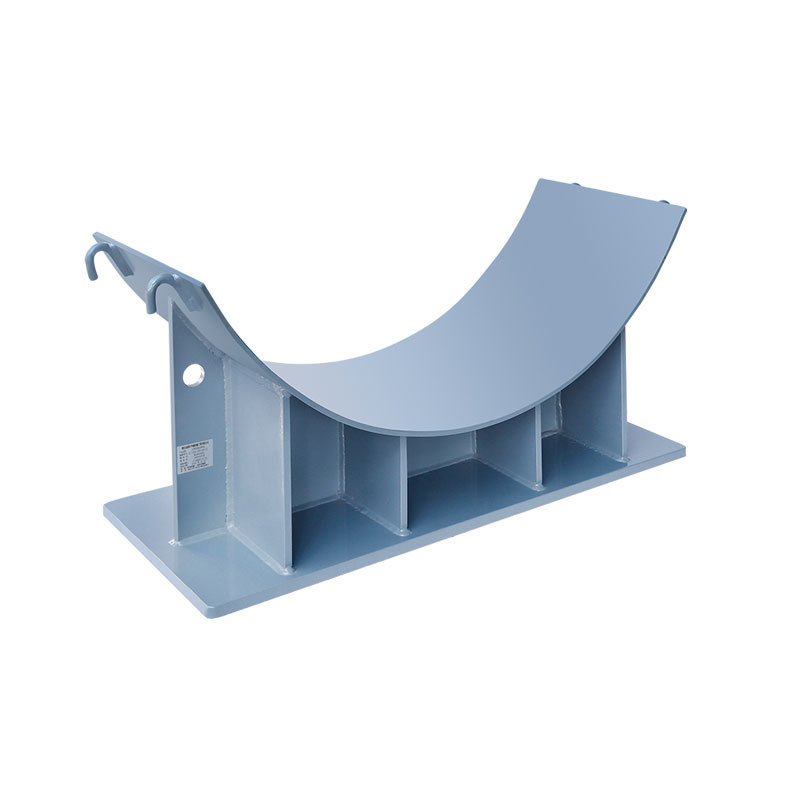

Welded spring shock absorber (straight tube trunnion)

X5

The upper pin seat is welded to the upper steel beam, and the lower pin seat is welded to the trunnion of the straight pipe (horizontal pipe, riser pipe)

32

Welded spring shock absorber (elbow trunnion)

X6

The upper pin seat is welded to the upper steel beam, and the lower pin seat is welded to the elbow trunnion (elbow)

Same as 32

Welded spring shock absorber (double trunnion)

X7

The upper pin seat is welded to the upper steel beam, and the lower pin seat is welded to the trunnions of the straight pipe on both sides of the pipe (horizontal pipe, riser pipe)

Same as 32

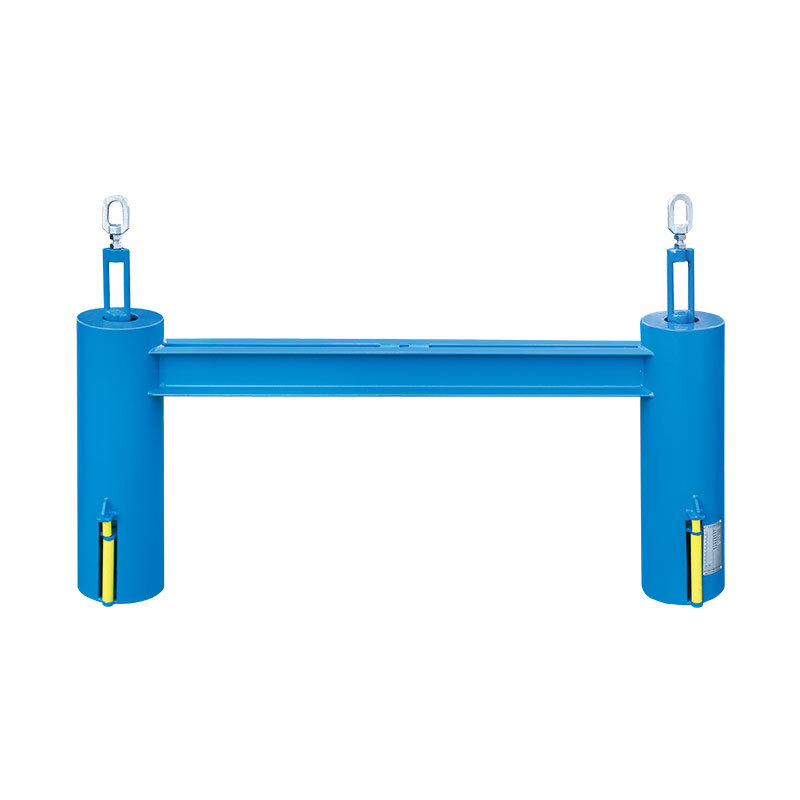

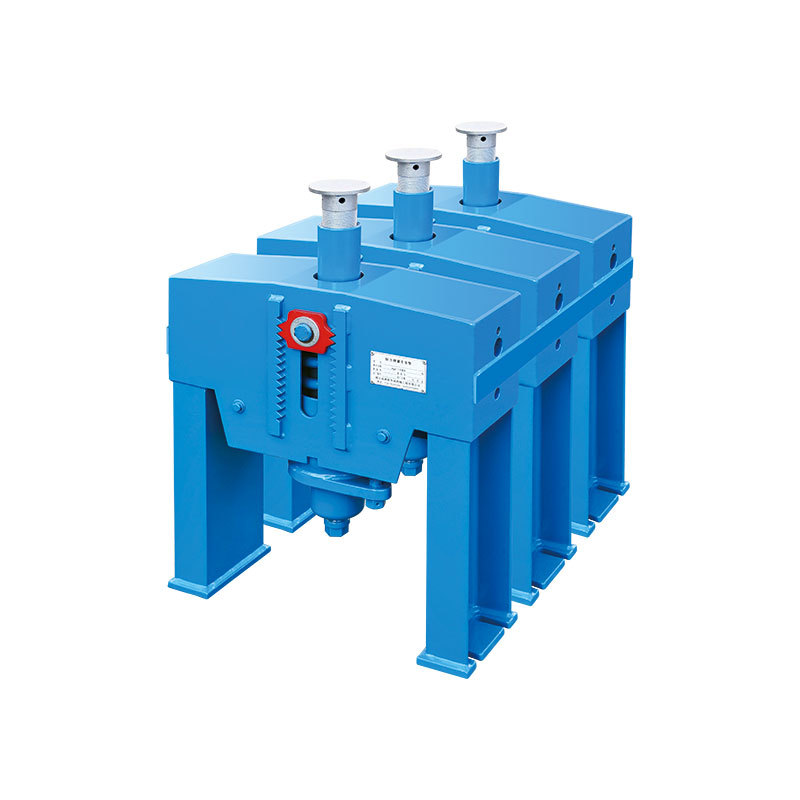

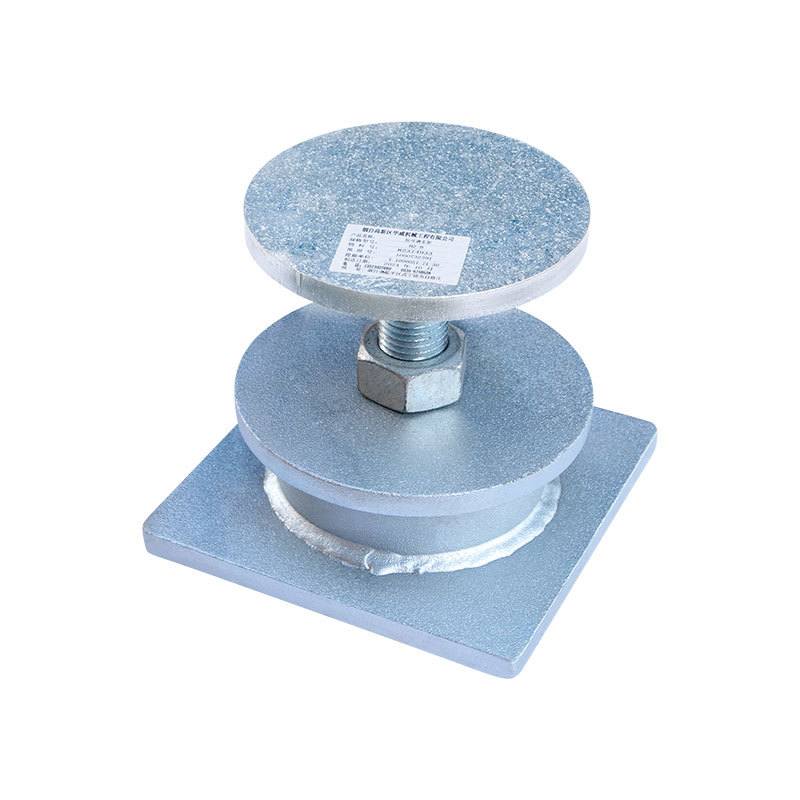

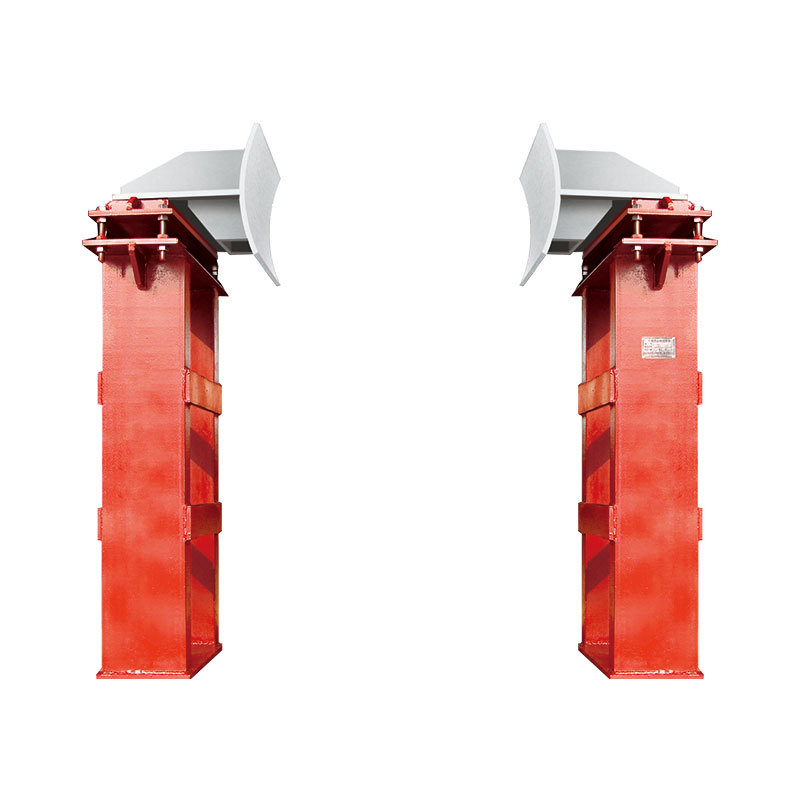

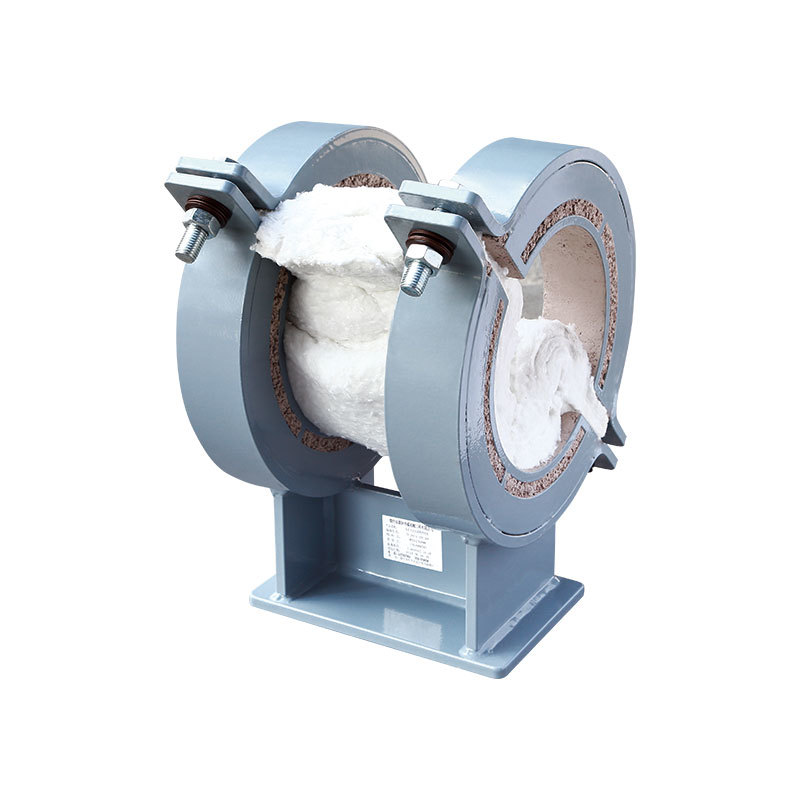

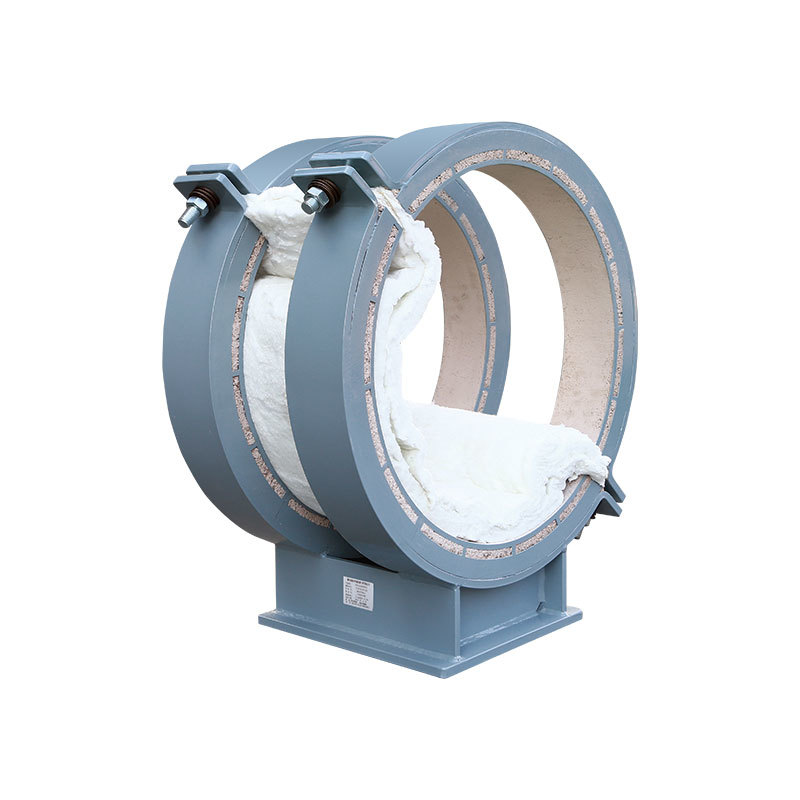

Equal-length double-spring shock absorber combination frame with variable angle

X8

The upper pin seat is welded to the upper steel beam, and the dynamic pipe clamp clamps the pipe or pipe trunnion.The angle between the shock absorbers is variable.

33

The angle is 90.Double spring shock absorber combination frame

X9

The upper pin seat is welded to the upper steel beam, and the dynamic pipe clamp clamps the pipe or pipe trunnion.The angle between the shock absorbers is 90%.

Same as 33

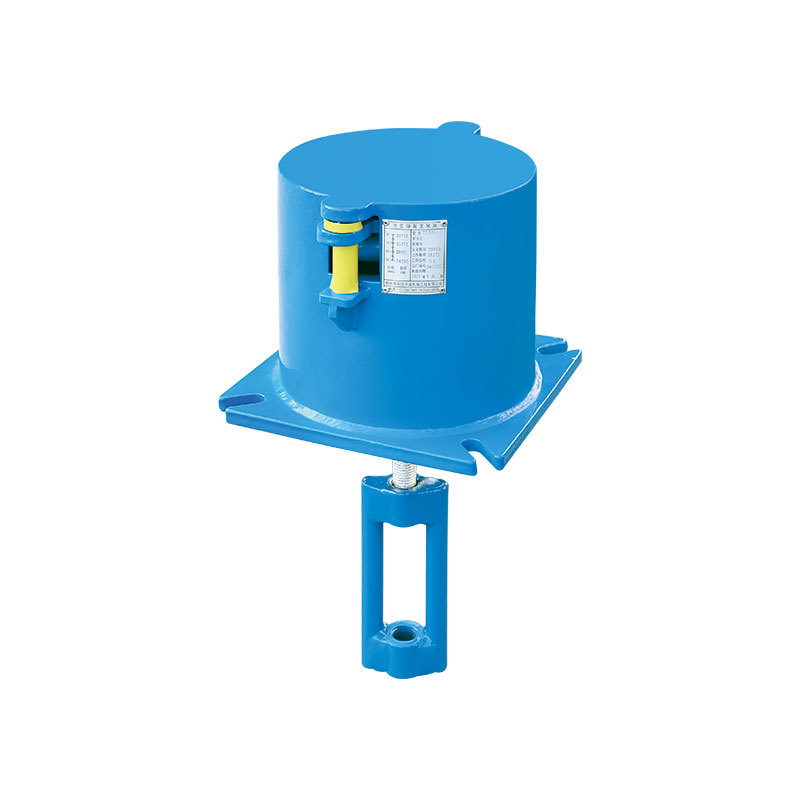

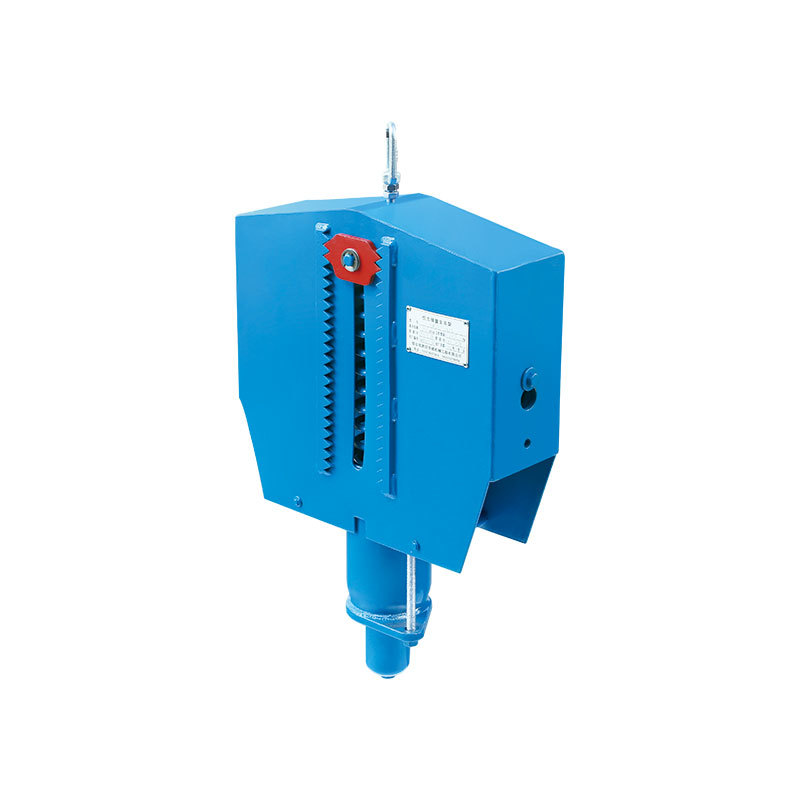

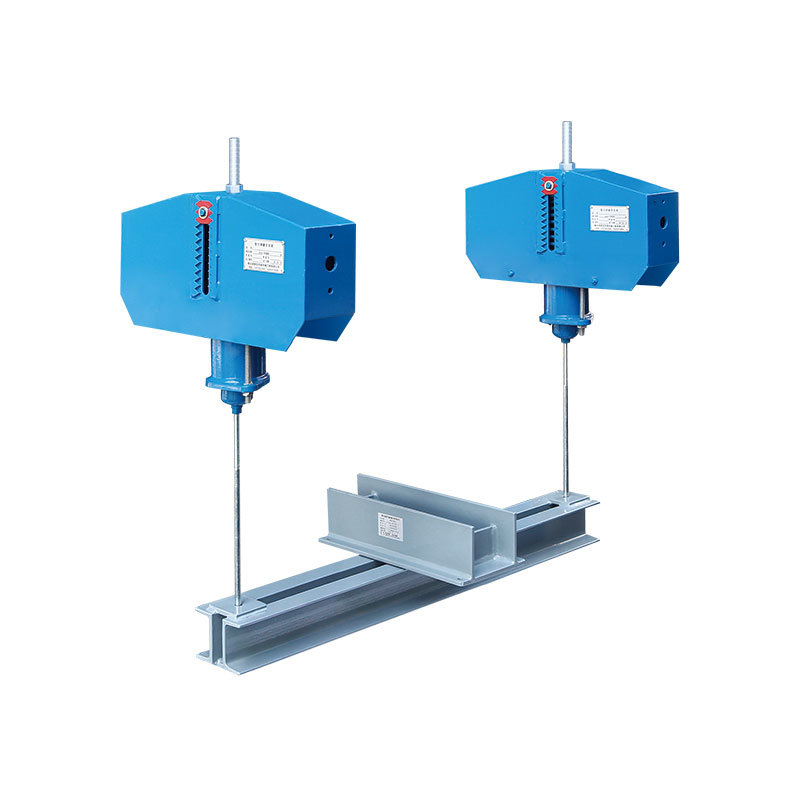

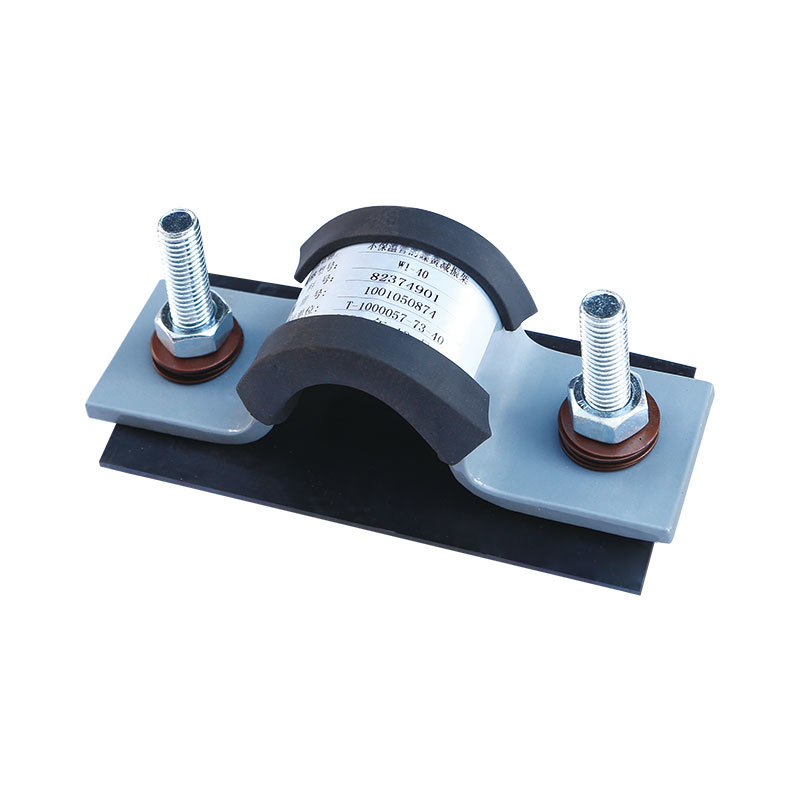

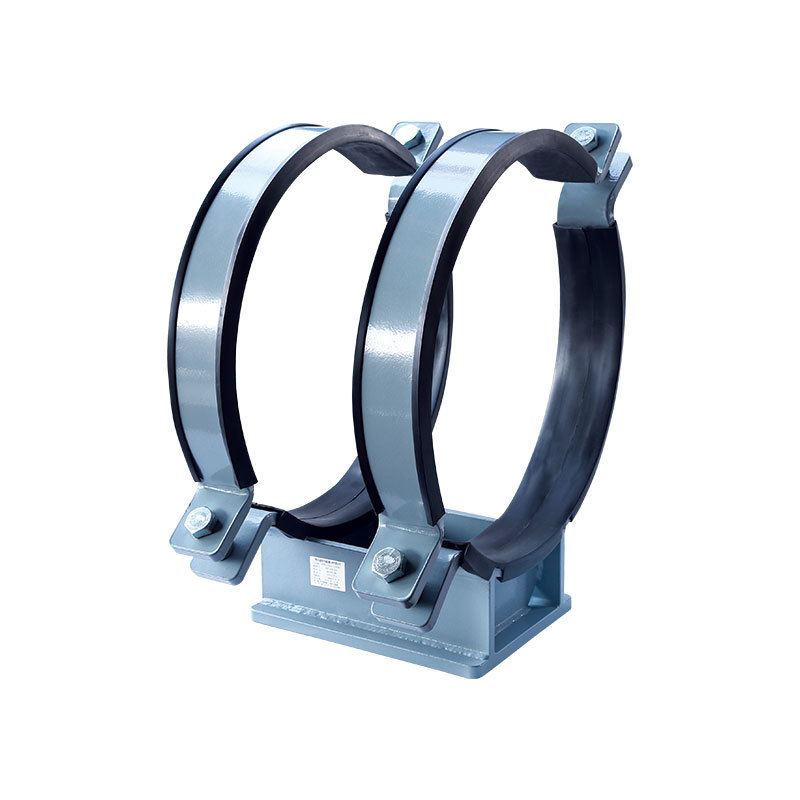

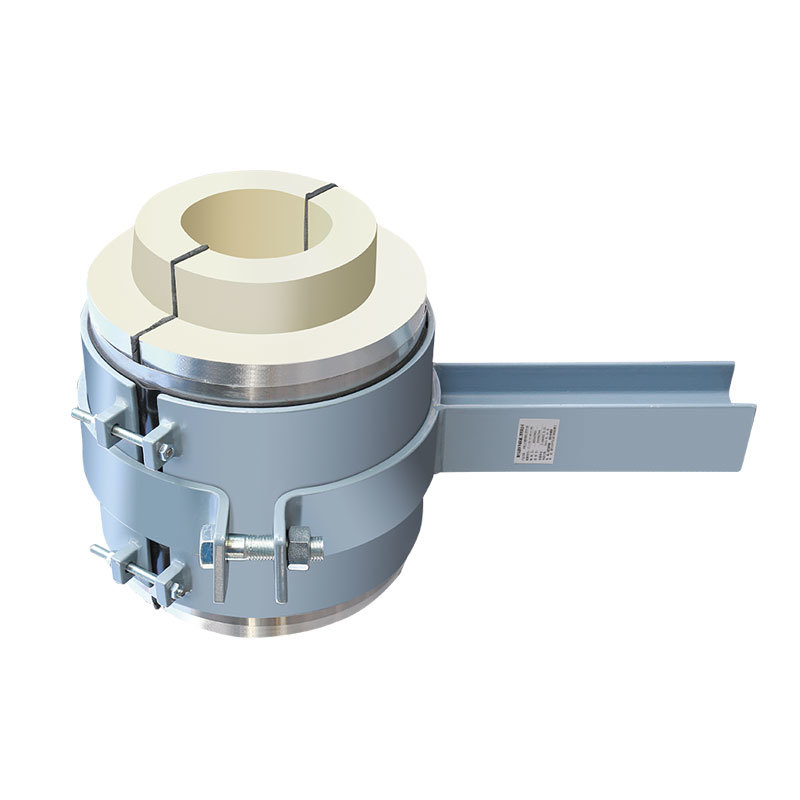

Equal-length double-spring shock absorber with variable angle

X10

The upper pin seat is welded to the upper steel beam, and a special dynamic pipe clamp clamps the pipe or pipe trunnion.The angle between the shock absorbers is variable.

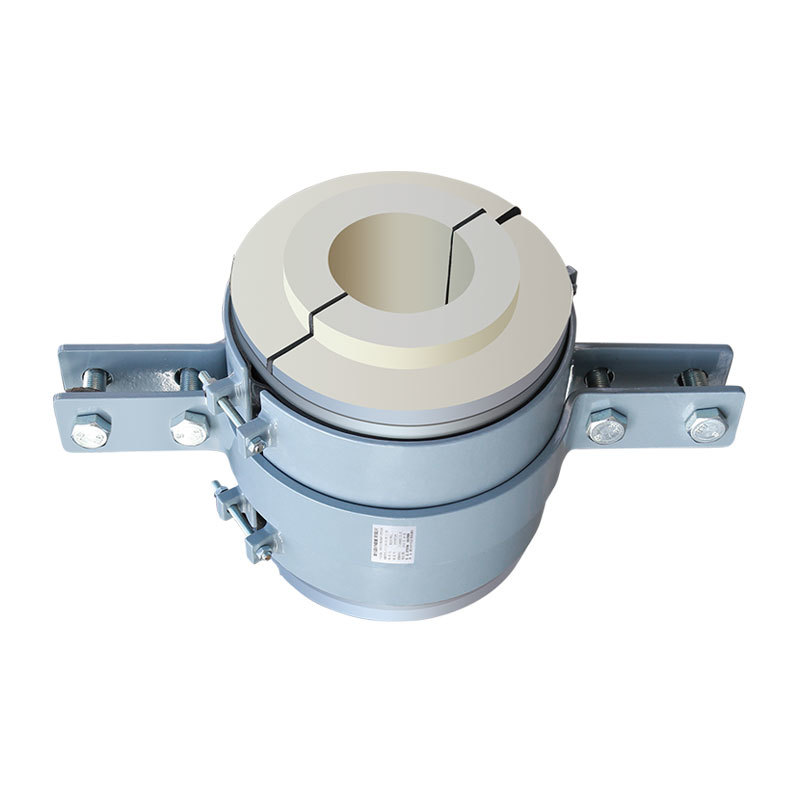

34

Double-spring shock absorber combination frame with an angle of 90°

X11

The upper pin seat is welded to the upper steel beam, and a special dynamic pipe clamp clamps the pipe or pipe trunnion.The angle between the shock absorbers is 90°.

Same as 34

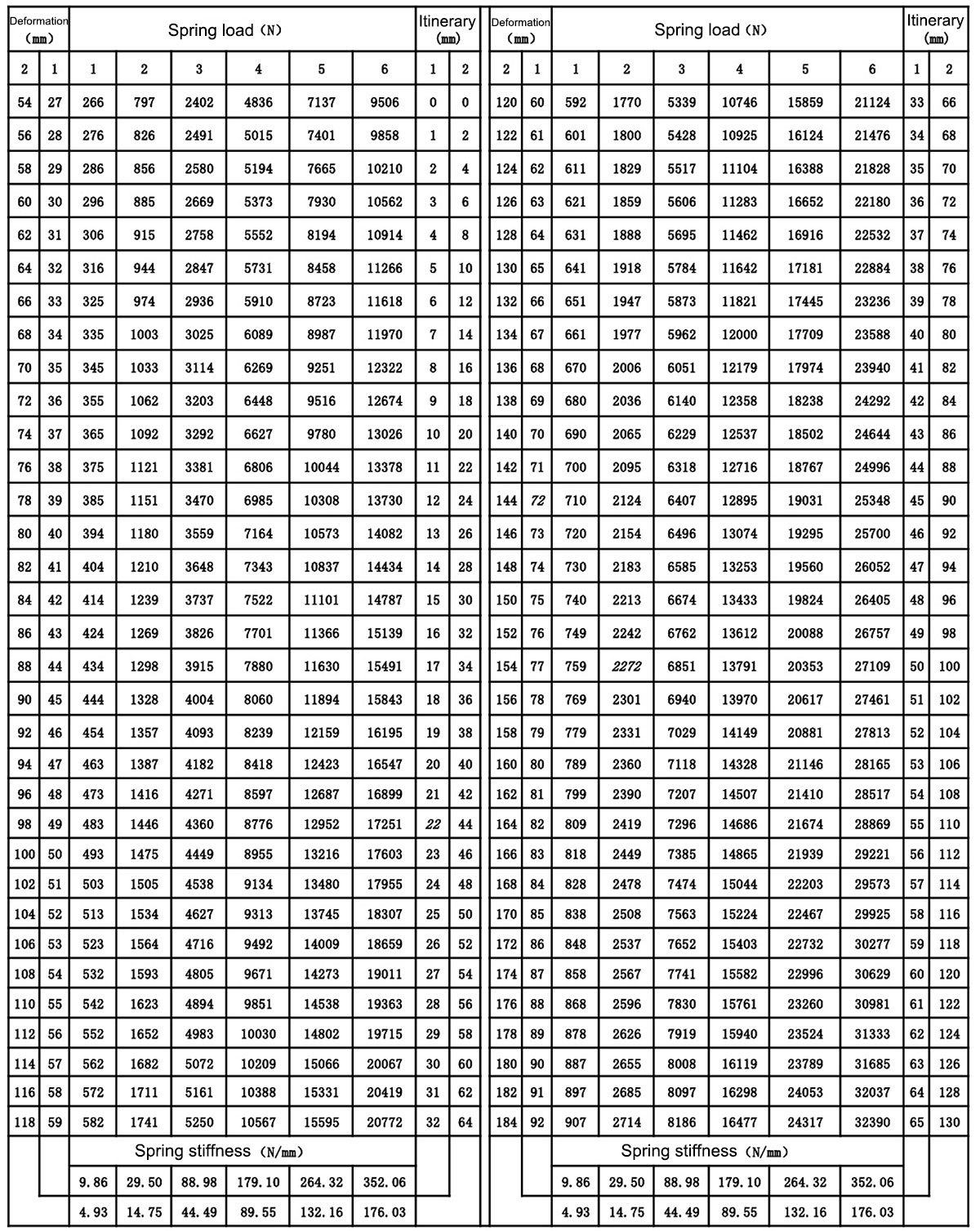

When designers and users choose spring shock absorbers, please refer to the “Spring shock absorber load-stroke table”.

Spring shock absorber load-itinerary

Note:

1. The stroke value in the table is the scale value on the shock absorber brand name.

2. The load value at position 0 is the initial working load of the shock absorber.

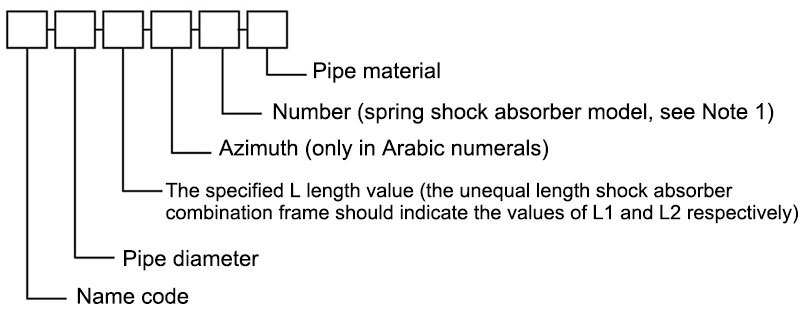

Spring shock absorber model notation:

Example: X9-200-1500-45-72132015(+10/ 8 (86)-15CrMo means that the name is X9, the pipe diameter is DN200-the specified length is 1500mm, the azimuth is 45°, the number or spring shock absorber model is 72132015 (+10/8186), and the pipe material is 15CrMo spring shock absorber.

Note 1: The number or model description of the spring shock absorber.The spring shock absorber model is represented by seven cells, as follows:

1

2

3

4

5

6

7

Product code

Type code

Load code

Itinerary code

Extension code

Pin hole diameter

Tuning parameters

First cell: Product code

The product code is represented by a single digit 7 (dynamic load components include: hydraulic damper, hydraulic damper auxiliary extension, spring shock absorber, limit dynamic load pipe clamp, pull strut, pin seat, etc.).

Cell 2: Type code

The type code is represented by two digits:

Basic shock absorber (rated load is not adjustable): 20

Adjustable shock absorber (rated load can be adjusted on site): 21

Cell 3: Load code

The shock absorber matching code is represented by one digit:

The maximum damping load is 907N:1

The maximum damping load is 2714N:2

The maximum damping load is 8186N:3

The maximum damping load is 16477N:4

The maximum damping load is 16477N:5

The maximum damping load is 32390N: 6

Cell 4: Itinerary code

The itinerary code is represented by one digit:

Damping stroke is ±65mm 1

Damping stroke is ±130mm 2

Chapter 5: Extension "Code

The extension code is represented by one digit:

No extension rod 0

With extension rod 1

Chapter 6: Pin hole diameter

The diameter of the pin hole is represented by three digits: the actual diameter of the pin hole at both ends of the shock absorber

Chapter 7: Tuning parameters

The tuning parameters are represented by multiple digits in parentheses: thermal displacement/damping load.The thermal displacement symbol of the pipe that shortens the length of the shock absorber is “+”, and the thermal displacement symbol of the pipe that lengthens the length of the shock absorber is “-”

Model example:

7 21 3 2 1 015 (+10/8186) represents an adjustable spring shock absorber with a damping load of 8186N, a damping stroke of ±130mm, an extension rod, a pin hole diameter of 15mm, and a thermal displacement of +10mm.

NO.34

Special dynamic pipe clamp type with angle spring shock absorber

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products